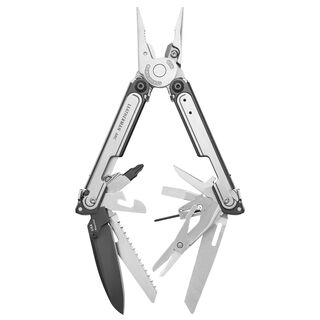

The pinnacle of multi-tools, ARC® is finally here. This premium multi-tool combines fan favorite implements with innovative materials and design. One of the features getting the most attention is the use of MagnaCut steel for the primary blade. This is a first for the industry and for a regular offering from Leatherman.

what is magnacut steel?

MagnaCut is a high-performance premium steel that hits the sweet spot of qualities that make a superior knife blade. It has excellent edge retention, toughness, and corrosion resistance. It is a relatively new steel on the market and was designed specifically as a knife steel. Leatherman has chosen to use this steel in the ARC to give our users the best possible cutting performance on the best multi-tool we’ve ever made.

But don’t take it from us. To find out more about MagnaCut, we went right to the source, the creator Dr. Larrin Thomas. The following interview was conducted via email.

“There are no real tradeoffs with MagnaCut. It performs very well in each category.”

Thanks for chatting with us, Larrin. We know our fans are excited to learn more about MagnaCut as they start using the ARC. For those who are new to your work, can you give our readers an overview of your background?

My father Devin Thomas is well known for making stainless Damascus for knifemakers and knife companies. When I was a teenager, he took me to several knife shows, and I heard from knifemakers about the steels they used and special heat treatments they performed. Many of them would promote secret methods and claim better performance than the competition. I was intrigued by this and tried to learn everything I could about steel metallurgy. Eventually, I got a PhD in metallurgy, and I work as a development engineer for automotive sheet steels. Because of my love of knife steels, I started a website, KnifeSteelNerds.com, where I write about metallurgy and perform experiments to learn things and report them to knife enthusiasts and knifemakers.

Can you give us a summary of that process and your goals/inspirations for creating a new knife steel?

When I first began learning about knife steel, one of the most exciting things to me was the development of new steels. Crucible's CPM-S30V was new, and I would ask the Crucible metallurgists about how a new steel was designed. How do you decide how much of each element to add to get the properties that you are looking for?

However, when I looked at the landscape of knife steels and played around with various models of steel design, originally, I didn't see anything that stood out where big performance improvements were possible. Eventually, I came across the idea of reducing the chromium content of stainless knife steels. In the past, Crucible had improved the performance of their older steel CPM-440V (renamed CPM-S60V) by reducing the chromium content to 14% which led to CPM-S90V and CPM-S30V.

Chromium is used for corrosion resistance: the chromium forms a chrome oxide at the surface that prevents rusting. However, some of that chromium forms a chromium carbide which leads to worse properties than non-stainless powder metallurgy steels which only have harder, smaller vanadium carbides. The chromium carbides also reduce corrosion resistance because the chromium content is locally lower surrounding the carbides.

So, despite the knife steels having 14-20% chromium, only about 10-12% of that is used for corrosion resistance and the rest goes to somewhat undesirable chromium carbides. I reduced the chromium content to ~11%, the amount that is used for corrosion resistance, and then carefully controlled the composition to avoid chromium carbides. The result was a steel with better toughness and corrosion resistance while maintaining similar hardness and edge retention to other stainless knife steels.

It was a true step forward in knife steel performance. But to get to the point of seeing if my idea would work, I had to present the idea to Crucible Industries who makes the powder metallurgy steel and Niagara Specialty Metals who hot roll and sell the steel.

I convinced them the idea had promise, and, fortunately, the steel worked as I promised on our first try.

Do you carry a Leatherman multi-tool? Or more broadly, what is your everyday carry?

I carry and have carried a wide range of knives, mostly folding knives though also one or two fixed blades. I carried a Leatherman Skeletool® for a while which I liked because its light weight and had a pocket clip, it could be carried more similarly to a pocketknife. Which also meant I had the benefits of a multi-tool as well.

“It's incredibly gratifying to see the steel I developed be used by great companies like Leatherman. It's surreal to see ‘MagnaCut’ displayed on excellent new products.”

We’re excited to release our newest multi-tool, the ARC. We’re confident that this is the best multi-tool we’ve ever made. It combines our FREE technology with new materials and includes many fan-favorite features. One of the new features, of course, is a primary blade made from MagnaCut. Can you speak to qualities of MagnaCut that make it especially well-suited for an everyday use knife in a multi-tool?

MagnaCut has an excellent balance to its properties in terms of edge retention, toughness, corrosion resistance, and sharpenability. There are no real tradeoffs with MagnaCut. It performs very well in each category. To get better performance in any one of them would necessitate a drop in one of the others. So, depending on your preferences you can sharpen to low angles to maximize cutting performance and edge retention, or beef up the edge for tough uses.

How do you feel MagnaCut and Leatherman fit together? In terms of commitment to quality, innovation, and values we may have in common.

Tim Leatherman's invention of his unique multi-tool created a new product category in the knife and tool world. I enjoy learning about innovations and innovators of the past (I recently published a book on the topic), and these are the people that inspire me with new steel developments.

How do you feel about MagnaCut being featured soon in Leatherman’s most premium tool?

It's incredibly gratifying to see the steel I developed be used by great companies like Leatherman. It's surreal to see "MagnaCut" displayed on excellent new products.

You touched on this a bit already, but are there any specific milestones or hurdles you had to overcome to bring MagnaCut to life?

MagnaCut was a culmination of my passion for knife steel and the journey I took to learn about metallurgy and steel design. So, it is hard to talk about MagnaCut without talking about my whole life, which might be a bit more than Leatherman fans want to read. I will say that after high school I was not on the fast track to a Ph.D. in any discipline, much less metallurgical engineering. I was at a junior college with no planned major, and I didn't even know if I was "college material." My math teacher Mr. Bowler gave me the confidence I needed to pursue engineering when I didn't think that was possible for me.

What’s next on the horizon for you?

I'm always working on new things for KnifeSteelNerds.com and my YouTube channel. Recently my father and I completed the biggest set of experiments ever done on the performance of pattern-welded Damascus steel. Nearly every experiment surprised me, and we had to come up with a lot of creative ways to figure out why we got certain results. While we found several scenarios when Damascus can have worse performance than expected, we found a few cases where the legends about Damascus are true. It's never boring because when the experiments are designed well there are always surprises.

Huge thanks to Larrin for taking the time to chat with us about MagnaCut.

If you’d like to learn more about knife steels, be sure to check out his blog. This post takes a deep dive into Larrin’s journey of creating MagnaCut.