It can take up to two years for a Leatherman multi-tool to move from concept to storefront. But you might be surprised to learn that the engineering doesn’t stop there.

To learn more about what happens after a new product enters the world, we chatted with Edward Whidden-River, Leatherman’s Manufacturing Engineering & Operational Excellence Manager.

He took us inside the Leatherman factory for a firsthand look at the people, machines, and processes that continue to improve on products long after they’ve been released.

“One of my favorite things I get to say about my job is: ‘It’s all made right here in town.’”

Hi, Edward. Thanks for taking the time to talk to us today. Can you introduce yourself and tell us a little bit about what you do here at Leatherman?

Absolutely, any time. My name is Edward Whidden-Rivera, and I am fortunate enough to be one of the engineering managers here at Leatherman Tool Group. I hold a Lean Six Sigma black belt from the American Society of Quality, a certification in production and inventory management from the Association of Supply Chain Management, and am a second-year master’s student at Portland State in the Engineering and Technology Management program.

I manage two fantastic groups of engineers that support operations, the OpEx team and the Manufacturing Engineering team. These teams focus on new equipment and automation as well as capital and continuous improvement projects related to the factory and her processes. In a short summary, we own the process and the sustained improvements we make here in Portland Oregon.

When most people think of engineering, they think of blueprints, prototypes, and all the work that goes into creating a finished product. But here at Leatherman, that’s not the full story. Give us a broad overview of what it means to continue to engineer a product after its release.

Yeah, the NPI [New Product Introduction] team works in collaboration with ours to get new products ready for production in a short time frame using our production part approval process.

But you’re right, it doesn’t tell the full story. Culturally, within Engineering at LTG [Leatherman Tool Group] there is a huge focus and passion for making, owning, and improving our product. Competitors might work hard to design a new tool, but once that process is over, it leaves to be produced overseas. The ownership is out of their hands. Our engineers revel in the fact that the process they own is merely a few feet from their office. It’s extremely hands on. They can give immediate feedback when improving product and, by extension, the lives of the people who work here every day.

In a broad sense at Leatherman, engineering never ceases. We continue to iterate, focusing on metrics like capability, productivity, and efficiency. All these directly impact the quality of our product.

“My favorite machines are here, and they help the people that use them. They produce higher quality parts, and they do it more efficiently than the competition.”

Is it fair to say that in three years’ time our newest multi-tool ARC® will be the same but it also might be different?

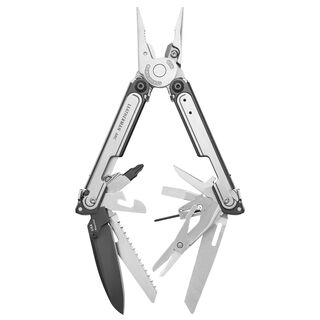

Yeah, that is fair to say. The reality is that the many different processes that make ARC will always be updated and improved. That may be through stamping, machining, jaws, components, files, saws, KB, or our assembly department. Each area has their own engineer embedded into the process who is constantly striving to make the process more capable. And while that may not mean a new implement in the ARC tool from my team, it means the quality of the parts being produced out of the factory are always getting better, regarding cosmetic and performance requirement.

The word capability comes up a lot when talking about multi-tools. A Leatherman multi-tool on your side makes you more capable of tackling everyday challenges. That’s one way to think about it. But in the world of engineering, capability has a different meaning, doesn’t it?

Yeah, you’re right, from a consumer’s perspective, having a Leatherman already makes them more capable of working through their unique task or challenge, but this EDC definition differs from how engineers see capability in some ways.

As it turns out, how our engineers measure capability is directly tied to the quality of our tools. If the readers have made it this far, I would encourage them to research Process Capability Index, and factors in a process that may affect an index like this. This metric we use at Leatherman helps us understand how the variation in process measures up to our specifications and statistically determines failure rates. Leatherman makes millions of tools each year, and we are constantly striving for capability indexes that put us with lower and lower failure rates every year.

In short, we measure the variation or voice of each process in Portland constantly. We plot this variation over time and watch for trends or specific events. We compare it to both the specifications given to us by customer feedback, but also to the statistical process limitations themselves. While the engineers around the factory love to show off their newest EDC item and its capabilities, when it comes to capability in the factory, the engineers hold a different meaning.

Can you give us an example of a process or material change that improved the team’s capability?

Yeah, absolutely. We are constantly improving with new technologies in the factory to stay competitive. ARC specifically has benefited from one of our most recent improvements.

We spoke earlier on variation in a process, and there is a generally accepted theory that each time a tool goes through a process a little more variation could be potentially added. Rarely does that variation shrink unintentionally. That’s pretty standard with most multistep processes.

Obviously, if you let it, that variation compounds. To control this, we often conduct something called a contribution study, so we understand how each step in the process contributes to the variation and changes the outputs of components/tools. If necessary, we then add a process that shifts that output, or may even shrink that level of variation.

But to shrink that level of variation can be very difficult. Most of that variation exists because each process cannot account for the previous variation that exists. Nor can it try and “redirect” that variation to a smaller amount of variation than came to it. If it could, these ‘smart’ machines would need to know “hey, this incoming part looks a little different, I will account for that and only move this grinding operation this much as opposed to the same every time”.

What we are talking about here is something called compliance, or a feedback loop. And this is precisely what one of our brilliant engineers had implemented for ARC key benchmarks. A machine that has a feedback loop on incoming material that allows us to take all upstream variation and move that.

All of this helped give the ARC the most capable knife blade we’ve ever made.

Ensuring Micra® knife blade components are perfect.

Walk us through a couple of your favorite machines and tell us how they’ve made a tool or a process better.

It’s hard to pick a favorite to be honest, though I can tell you what a few of my favorites have in common. They focus on four things.

1. The machines are here.

One of my favorite things I get to say about my job is “It’s all made right here in town”. The machines we operate are here. There is pride in that ownership. It may take engineers years to learn that lesson but a source of the joy you get from problem solving, is being there when the “aha” moment turns into a group of smiles from team members huddled around a machine, when you finally find a root cause, or a relationship between multiple variables you have been searching for to help optimize that process.

My favorite machines are the ones right outside my office.

2. They have improved the lives of the workers and operators who use them.

I am a firm believer that you give people the tools they need to do their job successfully. An easy thing to say, but much more difficult to implement. Believe it or not, those of you who are reading this are not the only customers my team has. The people that work on those machines day in and day out, the operators, the technicians, the family members at LTG, are also the engineers’ customers.

Their safety and their quality of their life at Leatherman are both metrics my teams put extreme priority on when scoping new equipment or improving process. My favorite machines give those operators a better quality of life, and security to create a safe environment.

3. They have improved the process capability of the parts being made to the specification of the customer.

Newer is not always better. And part of my team’s responsibility is to make sure that new equipment, or new processes are capable. Either by new grinding technology, new robotics, new vision systems, new machining practices, new stamping practices, new automated parts feeding, etc.

All these new technologies can mean a process that has a smaller window of variation. This has profound effects not just on our quality and ability to hit specifications. It also significantly reduces waste in a variety of categories. My favorite machines are the ones whose parts are capable. This directly means more quality tools off those machines.

4. They have improved the productivity and efficiency of the previous process.

It’s one thing to say, made in Portland. It’s another to say, we are staying here. And the way we stay here is by being more productive and efficient than our competition. Simply put, we produce more quality tools at a better rate than a high standard we hold ourselves accountable for. My favorite machines compete with last year’s standard and are more productive and efficient than last year’s process.

My favorite machines are here, and they help the people that use them. They produce higher quality parts, and they do it more efficiently than the competition.

Inspecting a fresh batch of jaw inserts.

Can you tell us how the QA process has changed since your time at LTG? What’s something that might surprise long-term Leatherman fans about the QA [quality assurance] process.

I’ll let Matt Connor, Leatherman Quality Manager, answer here.

“In the past ten years we have invested into dozens of automated measuring systems in our manufacturing facility to ensure we are always producing parts to specification. As Tim Leatherman said, ‘A Spec for Everything, and Everything to Spec.’

Every Leatherman tool goes through hundreds of quality checks, and we measure millions of parts per year to ensure that tools are always there to save the day and help our customers triumph over the unknown. We have an amazing quality team of dedicated professionals committed to ensuring that we manufacture the best multipurpose tools in the world from our Portland, Oregon facility.”

Edward’s everyday carry.

What’s a passion you have outside of work? How does your EDC play into it?

Every employee at LTG is an expert at their hobby, and each one is more unique and knowledgeable than the next. It’s why LTG has such a good culture. Naturally, the people making the tools, love using tools while doing the things they are passionate about!

Divers, rally sport drivers, VW van collectors, jewelers, alpinist, wood workers, family DIY fathers, free style skiers, sailors, mountain bike dads, Gambler 500ers, hunters, farmers, Ping Pong experts, Pickleball champions!

For me, if I am not at the factory in the winter, you can find me up on Mt. Hood, deep in the backcountry skiing powder and finding stuff to flip off with a group of friends. Out there in avalanche terrain, your gear and how to use it is everything. I tend to carry heavier tools than most people for EDC. But weight makes a difference when you’re carrying a beacon, shovel, probe, avy chute, water, gummy worms etc.

It’s not about carrying all the gear, or the newest gear but the right gear, and being practiced with it. This generally translates to me carrying a Topo Signal®, which has an easy access knife to remove frozen ice around bindings. A great set of pliers to repair buckles on boots or grab frozen things. A built-in Carabiner. A bit driver with bits specific to the fasteners on the gear I have, and maybe a few extra for traveling buddies to borrow.

Thanks, Edward!

A huge thank you to Edward for taking the time to talk to us.

ready to read more?

Interested in more insights from Leatherman’s engineers? Take a trip inside the Multi-tool Testing Lab with engineer Peter Parker where tools are put to their limits Enter the Torture Chamber. Or take a peek inside our factory when Essential Craftsman stopped by for a tour.